Applications and Industry Use Cases of Dual Circular Spline Harmonic Drives

Applications and Industry Use Cases of Dual Circular Spline Harmonic Drives

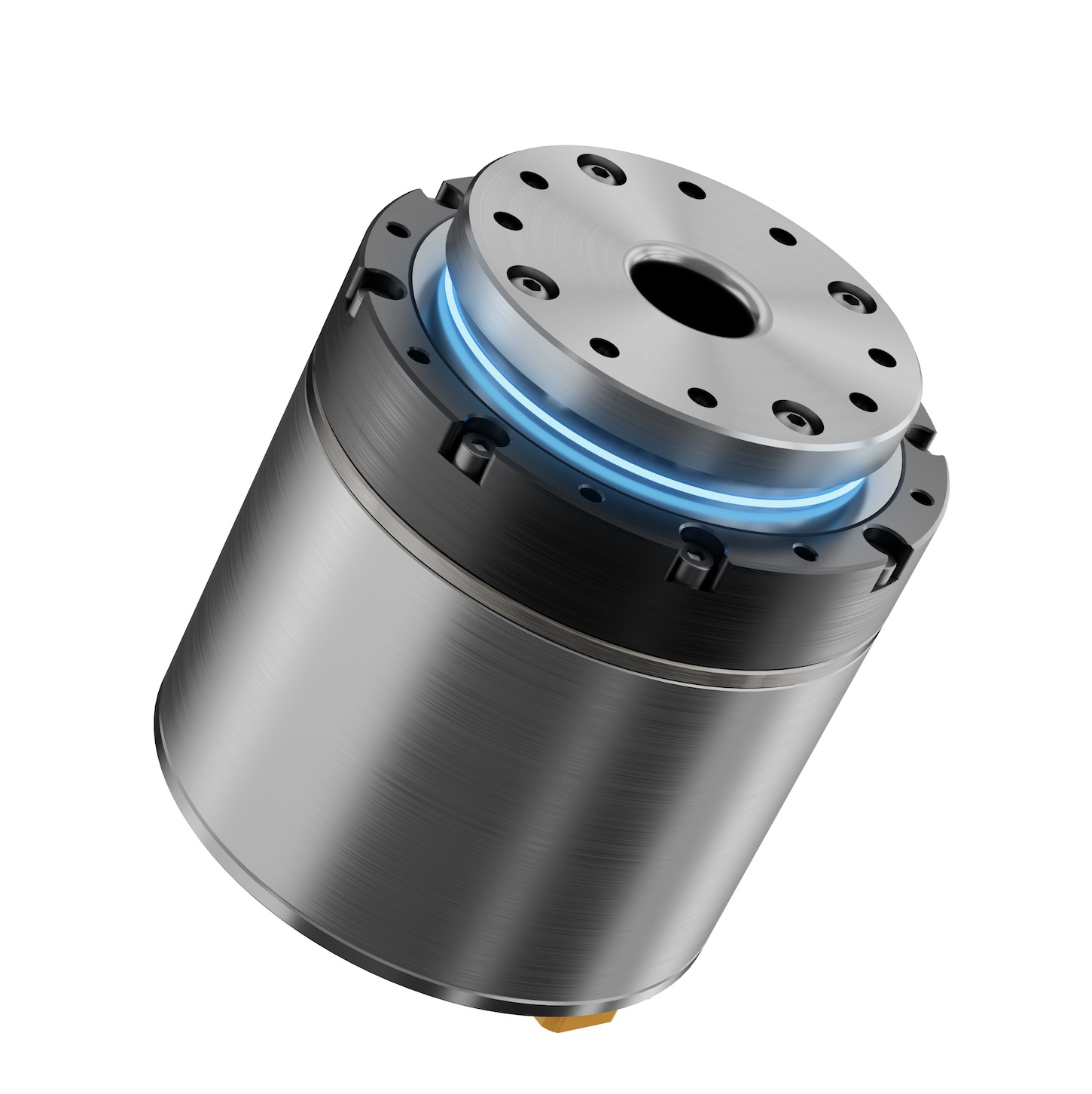

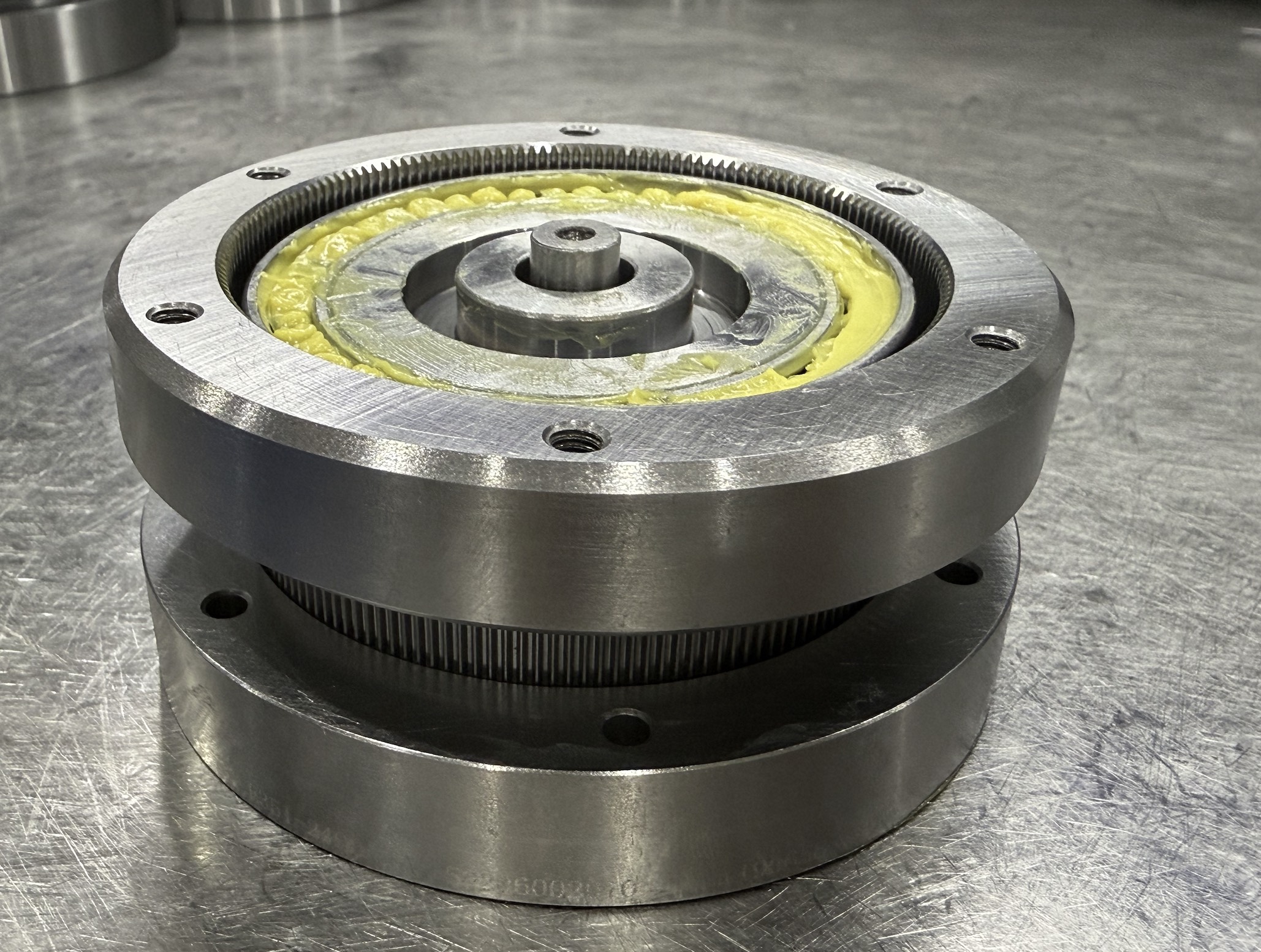

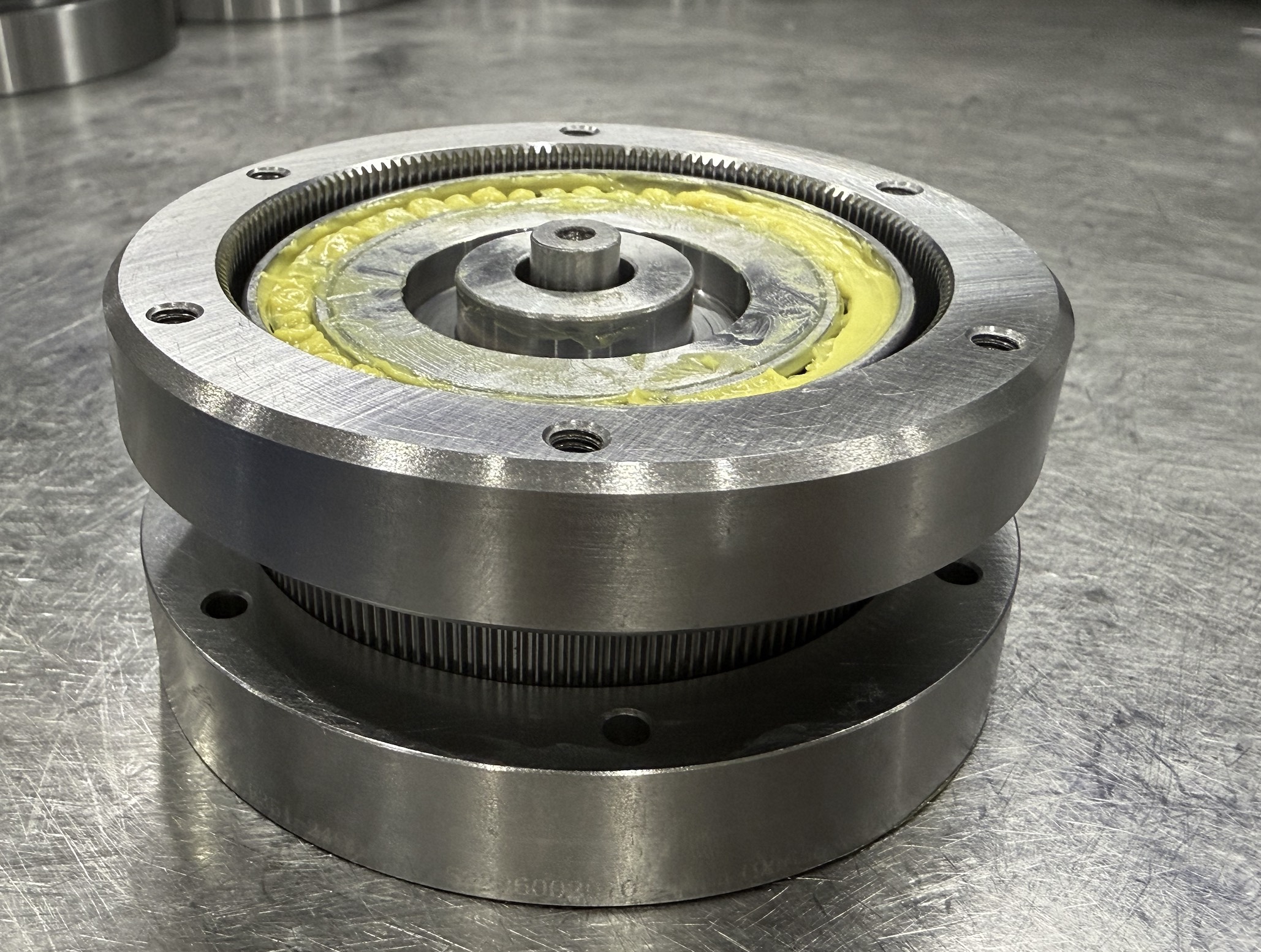

Dual circular spline harmonic drives are an advanced evolution of strain wave gearing, designed to provide higher torque, improved stiffness, and enhanced load distribution. These advantages make them highly valuable in industries where precision, reliability, and high-performance motion control are critical. The combination of compact design, zero backlash, and increased mechanical strength allows them to be used in applications ranging from robotics and aerospace to medical devices and industrial automation.

Robotics and Automation

Robotic Arms and Precision Manipulators

- In industrial robotics, high-precision movement with zero backlash is essential for tasks like pick-and-place, welding, and assembly.

- Dual circular spline harmonic drives improve torque transmission and rigidity, ensuring stable and precise robotic motion, even under heavy loads.

- Collaborative robots (cobots) benefit from the smooth operation and high repeatability of these drives, enabling safe human-robot interactions.

Humanoid and Service Robots

- Humanoid robots require high-torque and lightweight actuators for fluid, human-like movement.

- The increased stiffness and load-sharing capability of dual circular spline harmonic drives help achieve stable and controlled articulation, improving their ability to perform tasks requiring fine motor control.

2. Aerospace and Defense

Satellite Positioning Systems

- Harmonic drives play a critical role in the motion control of satellite solar panels, antennae, and cameras, where precision and zero backlash are essential for accurate positioning in space.

- Dual circular spline configurations provide enhanced durability and torque handling, crucial for long-term operation in extreme environments.

Aviation Actuation Systems

- Aircraft rely on precise control mechanisms for adjusting flight surfaces, landing gear deployment, and sensor stabilization.

- Dual circular spline harmonic drives contribute to lighter, more efficient actuation systems with superior rigidity and long-term reliability.

Military and Defense Applications

- Military-grade robotics and autonomous defense systems require robust, high-torque gearing to operate in harsh conditions.

- Dual circular spline harmonic drives improve shock resistance and mechanical efficiency, making them suitable for unmanned aerial vehicles (UAVs), robotic exoskeletons, and targeting systems.

Medical Equipment and Surgical Robotics

Surgical Robots and Robotic-Assisted Procedures

- High-precision robotic surgical systems (e.g., Da Vinci Surgical System) require smooth and backlash-free motion for delicate procedures.

- Dual circular spline harmonic drives provide high torque in a compact size, ensuring steady and precise control of robotic surgical arms.

Medical Imaging and Diagnostic Devices

- MRI and CT scanners use precise motion control for table positioning and scanning mechanisms.

- The vibration-free operation of dual circular spline drives enhances image accuracy and patient safety.

Prosthetics and Rehabilitation Robotics

- Advanced prosthetics and exoskeletons require lightweight, high-torque actuators to mimic natural movement.

- The improved stiffness and torque-handling of dual circular spline harmonic drives enable smoother and more responsive motion, benefiting mobility-impaired individuals.

Industrial Automation and Machine Tools

CNC Machines and Precision Manufacturing

- Computer numerical control (CNC) machines rely on precise rotary motion for cutting, milling, and engraving.

- Dual circular spline harmonic drives provide zero-backlash operation, ensuring high-accuracy machining with minimal vibration.

Semiconductor Manufacturing

- Semiconductor fabrication requires high-precision positioning systems for wafer handling and lithography.

- The compact and rigid nature of dual circular spline harmonic drives makes them ideal for high-speed, high-accuracy automation.

Energy and Renewable Technologies

Wind Turbine Pitch Control Systems

- Wind turbines need precise pitch control to adjust blade angles for optimal energy generation.

- Dual circular spline harmonic drives enhance torque stability and lifespan, ensuring efficient operation in varying wind conditions.

Solar Panel Tracking Systems

- Solar farms utilize tracking mechanisms to follow the sun’s movement, maximizing energy capture.

- Harmonic drives with dual circular splines improve positioning accuracy and system durability, leading to higher energy efficiency.

Space Exploration and Research

Robotic Rovers and Planetary Exploration

- Space missions, such as NASA’s Mars rovers, require durable, high-precision actuators for mobility and instrument control.

- The dual circular spline design enhances load capacity and longevity, ensuring smooth operation in extreme environments.

Telescopes and Observatories

- Large observatories and space telescopes need ultra-precise motion control for lens adjustments and tracking celestial objects.

- The zero-backlash and high-torque capabilities of dual circular spline harmonic drives contribute to stable and accurate movement, essential for high-resolution imaging.

Conclusion

The dual circular spline harmonic drive has become an essential technology in industries demanding high precision, durability, and enhanced torque capacity. From robotics and aerospace to medical and industrial automation, its ability to provide smooth, backlash-free motion with superior load handling makes it a preferred choice for critical applications. As technology advances, the continued evolution of harmonic drives will further enhance their performance, expanding their applications into even more demanding fields such as autonomous systems, deep-space exploration, and next-generation manufacturing.