A Joint Module is a mechanical device whose main function is to convert linear motion to rotational motion, while it can also achieve reverse conversion, that is, to convert rotational motion to linear motion. The device is usually driven by an electric motor.

In the application of robots, Joint Modules are mainly distributed in joints that require large-angle rotation, such as shoulders and hips, and their main components include motors, reducers, encoders, etc. However, due to the power density limitations of the motor and reducer, the application of Joint Modules in humanoid robots is limited.

When the power is switched on, the motor begins to work, producing a rotating torque. This torque is transmitted through the reducer, the main role of the reducer is to reduce the speed and increase the output torque, so that the Joint Module can output enough force to drive the robot joint to rotate.

Encoders play a key role in this process. It is used to monitor the rotation Angle and speed of the Joint Module, convert the motion state into an electrical signal, and then feed back to the control system. The control system can precisely control the running state of the motor according to these feedback signals, so as to realise the precise movement of the Joint Module.

In addition, the Joint Module may also contain other components, such as bearings and sensors. Bearings are used to support rotating parts to reduce friction and wear; The sensor is used to monitor the operating state of the Joint Module, such as temperature, vibration, etc., to ensure its stable operation.

In general, the working principle of the Joint Module is to generate rotating torque through the motor, which is transmitted and adjusted by the reducer to achieve rotational motion, and is precisely controlled and monitored by components such as encoders and sensors. In this way, the Joint Module can drive the robot joint to complete a variety of complex rotating actions, so as to achieve various functions of the robot.

Main Function

- Converts linear motion to rotational motion, or vice versa.

- Provides torque and power to drive robot joint movement.

- Achieve accurate motion control to meet the various motion needs of the robot.

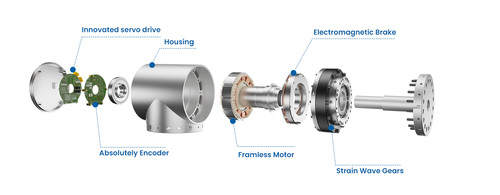

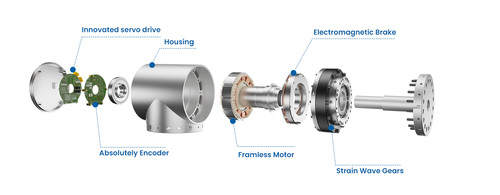

Basic Structure

- Motor: The power source of the Joint Module, responsible for generating the rotating torque.

- Reducer: Reduce the speed of the motor and increase the output torque.

- Encoder: detects the rotation Angle and speed of the Joint Module and feeds the information back to the control system.

- Other components, such as bearings, sensors, etc., for supporting rotating parts, monitoring operating status, etc.

Working Principle

- The motor is energised to produce a rotating torque.

- Torque is transmitted through the reducer, reducing the speed and increasing the torque.

- The encoder detects the rotation Angle and speed and feeds the information back to the control system.

- The control system accurately controls the running state of the motor according to the feedback information.

- The Joint Module outputs the desired rotational or linear motion.

Advantages of Joint Modules

- High accuracy: Joint Modules provide very precise and controlled motion.

- Strong power: The Joint Module can provide strong torque and power.

- Good durability: Joint Modules are very durable and can withstand harsh environments.

- Versatility: Joint Modules can be used in a variety of applications.

- High cost performance: Joint Modules have a high cost performance compared to other types of actuators.

Future Development of Joint Modules

Joint Modules are indispensable components in various industrial fields. With the continuous progress of technology, the performance and function of Joint Modules will also continue to improve, and will be more widely used in the future.

Sum Up

A Joint Module is a kind of mechanical device that converts linear motion into rotary motion or vice versa, which is widely used in robotics, automation, manufacturing, aerospace, automotive and other fields. The Joint Module has the advantages of high precision, strong power, good durability, strong versatility, high cost performance, and will be more widely used in the future.